STEEL PRODUCTS AND VARIOUS CONTAINERS

Our production

The main objective of ALGA Concern is to provide high quality, safe metal construction products and other manufactured products, as well as design, construction and transport services that meet the needs and expectations of our customers. The Group’s quality, environmental and occupational health and safety policy is the management of all interrelated processes in order to ensure the quality of products and services, to continuously improve quality indicators, to reduce negative impacts on employees and the environment, to reduce the likelihood of occupational diseases, hazardous and dangerous accidents at work, and to ensure the effectiveness of environmental protection and occupational safety and health.

Retractable open/closed waste containers with a capacity of 30 m3

The container is designed to be hoisted onto the machine using a hoist. Hook height 1570 mm (DIN 30722). Steel sheets are used: 4 mm for the bottom, 3 mm for the outer walls and doors. The bottom is provided with a rainfall water outlet. A door with a lock and a safety opening on the side is fitted at the rear of the container. All metal surfaces shall be coated with an alkyd coating according to the customer’s requirements. The sides of the open container may be fitted with hooks for the attachment of a tarpaulin cover. Products are guaranteed for 2 years.

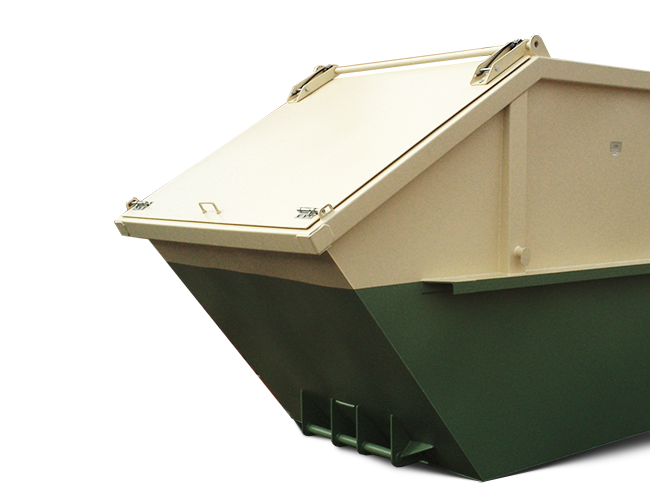

Open/closed stackable waste containers of various capacities

Containers can be adapted to be lifted onto the machine with a hoist. Steel sheets are used for production: 5 mm for the bottom and 3 mm for the outer walls. The bottom is provided with a rainfall water outlet. All metal surfaces are coated with an alkyd coating according to customer requirements. The sides of the open container shall be fitted with hooks for the attachment of the tarpaulin cover. Products are guaranteed for 2 years.

Building / metal structures

- Weights;

- Communications;

- Columns;

- Armature frames.

Retractable container for biofuel (up to 40 m3) with plywood

Standard external dimensions: 6800 x 2410 x 2540 mm. The production is carried out according to the project LST EN 1090-2, EXC1 workmanship class. Manufacturing dimensional tolerances according to design and LST EN 1090-2- tolerance class 1. Material certificates in accordance with LST EN 10204 and LST EN 1090-2. Pipes and profiles can be assembled (joined) from parts by welding. Weld preparation in accordance with LST EN ISO 9692 Part 1. Weld quality level C in accordance with LST EN ISO 5817. Surface cleaning in an abrasive blasting chamber to cleanliness class Sa2,5 according to LST EN ISO 8501-1. Exterior of the container frame: priming-painting with alkyd primer-paint 120 microns thick, according to customer requirements. Degree of preparation of external surface joints, edges and other areas with surface defects P2 according to LST EN 8501-3. Declaration of conformity in accordance with LST EN ISO/IEC 17050-1 and LST EN 1090-2 on the basis of the production control system certificate. Inside the frame, moisture-resistant veneer is fixed. Warranty 2 years.

Concern “ALGA”

Company code: 151299819

VAT: LT512998113

Address: Gamyklų g. 4, LT 68108 Marijampolė

Phone